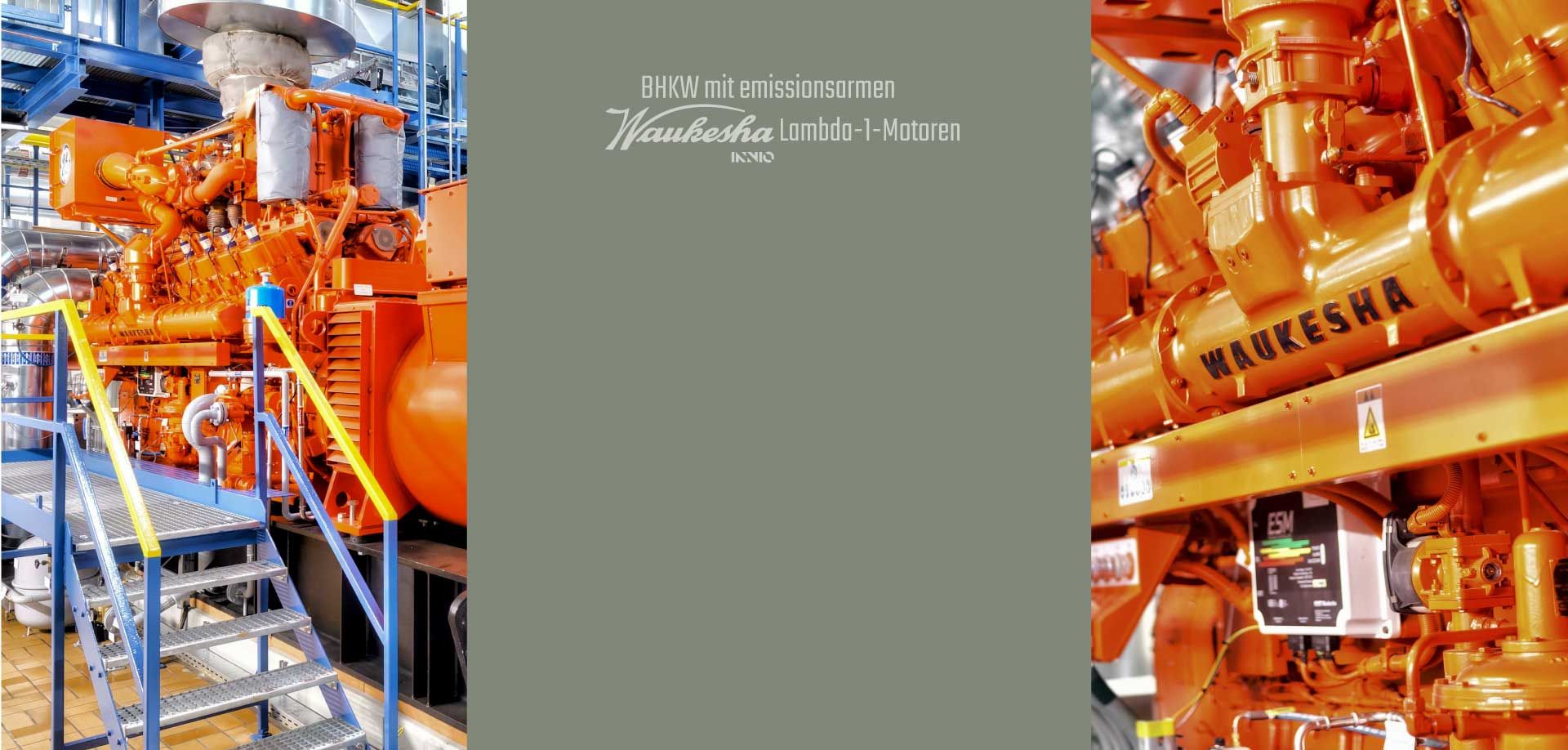

BHKW-Modernisierung am Flughafen Hamburg abgeschlossen

Eine der betriebsältesten BHKW-Anlagen Deutschlands auf dem Gelände des Flughafen Hamburgs wurde von 2021 bis 2023 Schritt für Schritt bei laufendem Betrieb durch die S&L Energie-Projekte GmbH modernisiert. Aus Gründen des veränderten Bedarfs wurden letztlich allerdings nur 4 statt der ursprünglich geplanten 6 Waukesha Gasmotoren erneuert. Auch die Anlagenperipherie wurde umfassend modernisiert.